From ancient times to the present, people will bring gifts when visiting relatives and friends. This is a traditional etiquette and custom since the Middle Ages. When visiting relatives and friends far away, they often bring some special products of their hometown or their own packaged in aluminum foil bags. The special snacks and dry goods of the masterpieces show more sincerity and affection. The so-called courtesy is light and affectionate, and the important thing is that kind of heart.

However, some things are ready-to-eat, and they will easily deteriorate when they are carried. Therefore, there are many things that are very delicious, but they cannot be taken away. Mildew and deterioration may also be caused by the loss of the original taste of the food due to too long time.

With the development of science and technology, these problems have been solved, and if necessary, the food can be prevented from spoiling on the way, and the flavor of the food will not be damaged. Vacuum packaging has a good effect of preventing the entry of air, resisting external pressure, and maintaining the freshness of food. When visiting relatives and friends, always keep aluminum foil bags at home for packaging, which is more face-saving.

What is an aluminum foil bag?

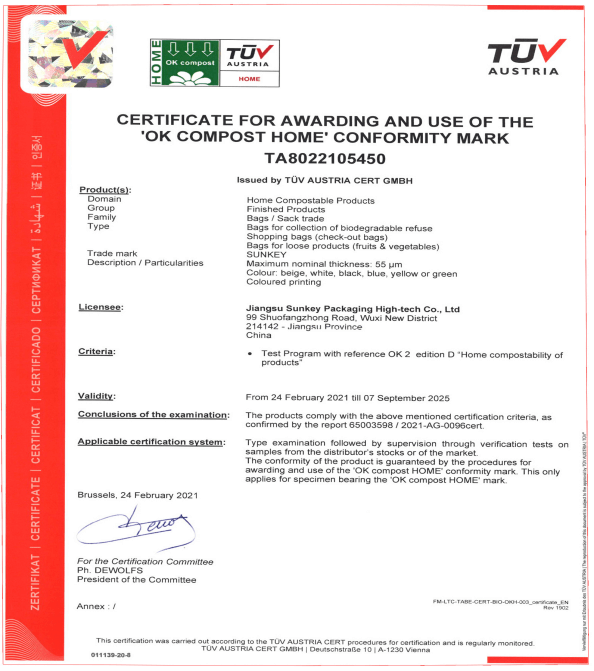

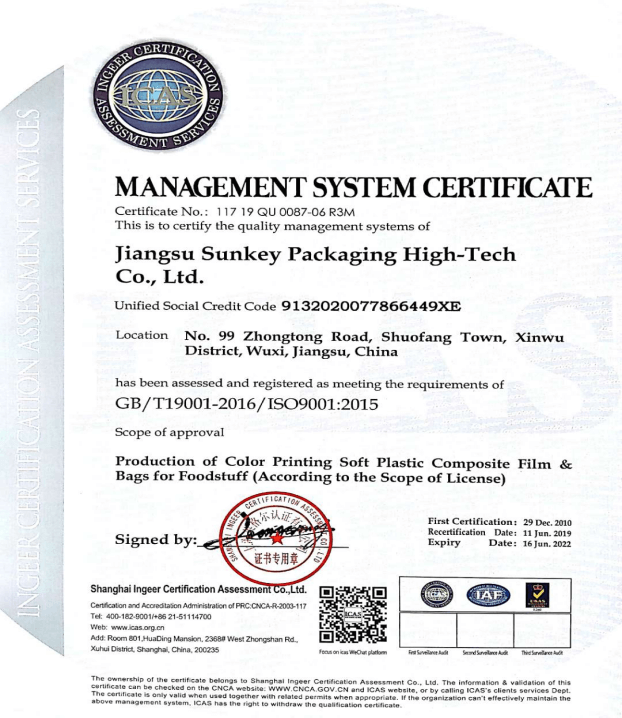

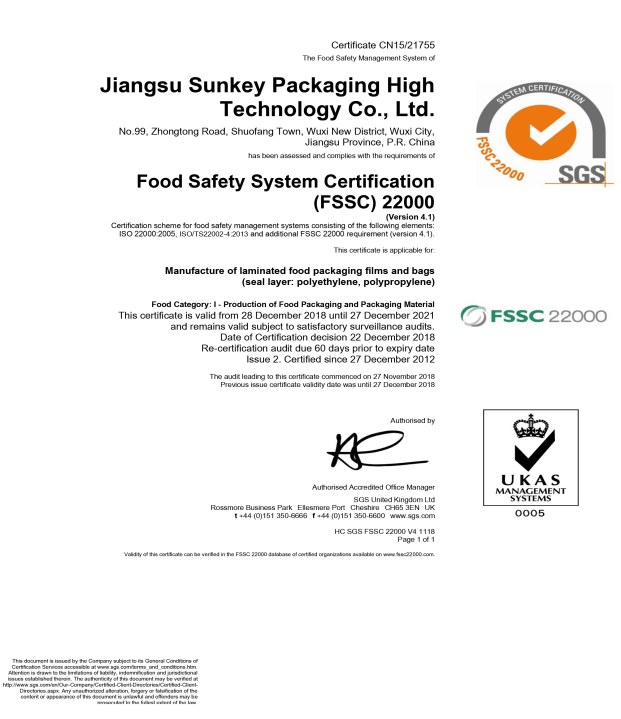

The aluminum foil bag is a bag made of a variety of plastic films after compounding and then passing through a bag-making machine. It is used to package food, pharmaceutical industrial products, and daily necessities. Such products are suitable for moisture-proof, light-proof, and vacuum packaging of large-scale precision machinery and equipment, chemical raw materials, and pharmaceutical intermediates. The four-layer structure is mostly used, which has good water and oxygen barrier functions. The products must be tested by GB and ASTM standards, and the products meet the requirements of environmental protection (third-party test reports can be provided).

Common materials of aluminum foil bags

PET/AL/PE PET/NY/AL/PE PET/NY/AL/CPP.

Foil Bag Thickness

70 ~ 180-micron bag shape: three-side sealing, self-supporting zipper bag, yin and yang bag.

Aluminum foil bag product features Appearance

Opaque, silver-white, reflective, with good barrier properties, heat-sealing properties, optical shading properties, high-temperature resistance, low-temperature resistance, oil resistance, fragrance retention; non-toxic and tasteless; softness, and other characteristics.

Aluminum foil bag product structure

PET/AL/PET/PE. Products with different composite materials and thicknesses can be customized as required. Storage environment temperature ≤ 38 ℃, humidity ≤ 90% 5. General product specifications: thickness 0.10mm and 0.14mm, three-side sealing, edge sealing 10mm, product specifications, and dimensions can be customized according to customer needs.

Scope of application of aluminum foil bag

(1) Suitable for all kinds of circuit boards, electronic products, precision machinery parts, consumer goods, industrial products, and another packaging. For example PC board, IC integrated circuit, electronic components, various LED industry SMT, lamp belt packaging, precision hardware, auto parts, and another packaging.

(2) Food packaging: milk, rice, meat products, dried fish, aquatic products, preserved meat, roast duck, roast chicken, roast pig, quick-frozen food, ham, cured meat products, sausages, cooked meat products, pickles, bean paste, Preservation of fragrance, quality, taste, and color of seasonings.

Foil Bag Features

(1) Strong gas resistance, oxidation resistance, waterproof, moistureproof.

(2) Strong mechanical properties, high blast resistance, strong puncture resistance, and tear resistance.

(3) High-temperature resistance (121℃), low-temperature resistance (-50℃), good oil resistance, and fragrance retention.

(4) Non-toxic and tasteless, in line with food and drug packaging hygiene standards

(5) Good heat-sealing performance, good flexibility, and high barrier performance.

The usefulness of aluminum foil bags

As the name suggests, aluminum foil bags are not plastic bags, and may even be better than regular plastic bags. When you need to refrigerate or pack your food now, and you want to keep the food fresh for the longest possible time, which packaging bag should you choose? Don’t worry about which bag to choose, aluminum foil bags are the best choice.

The surface of the ordinary aluminum foil bag is generally light-resistant, that is, it does not absorb light and is composed of multiple layers. Therefore, aluminum foil paper not only has good shading performance but also has strong insulation performance. The aluminum component is in it, so it also has good oil resistance and softness.

With the continuous exposure of counterfeit production and sales, especially the safety accident of plastic bags, people’s primary concern is not the function of the packaging bag, but its safety. However, consumers can rest assured that aluminum foil bags are non-toxic without a special smell. Absolutely green production products, environmental protection products, but also in line with the national health standards of aluminum foil bags.

Classification of aluminum foil bags

Food military medicinal aluminum foil bags, aluminum foil bag, aluminum foil bag, electronic aluminum foil bag, aluminum foil bag, the intermediate of aluminum foil bag, vitamin APIs to aluminum foil bags, aluminum foil bags, self-adhesive aluminum foil bag, particles in aluminum foil bag aluminum foil bags, aluminum foil bag, energy-saving aluminum foil bag powder, moisture-proof aluminum foil bag, high-temperature resistant aluminum foil bag, 25 kg aluminum foil bag, other aluminum foil bag

Today we talk about the classification of aluminum foil bags:

Because the raw materials contain aluminum foil, aluminum foil bags and aluminized bags are often confused. Aluminum foil bags have many classifications, names, and characteristics, which make it difficult to distinguish them. Today we will sort them out:

There are generally five types of aluminum foil bags according to the material:

Yin-yang bag: one side is a transparent composite material, the other side is aluminized material, the appearance is silver-white, and the surface is bright

Light aluminum bag: Aluminized material, silver-white appearance, bright surface.

Matt aluminum bag: aluminum-plated material, silver-white appearance, matte surface, black surface, matte surface

Matt gold bag: Aluminized material, dark golden appearance, matte surface, black surface, matte surface.

Pure aluminum bag: pure aluminum material, the appearance is silvery white (prefers to porcelain white), the surface is shiny and has a great texture.

The above is the classification of five types of aluminum foil bags. The materials are different, the appearance and color are different, and the hand feel is also different.

From the material point of view, pure aluminum bag, high purity, aluminum alloy mixed with composite material.

In terms of cost, the price of pure aluminum bags is higher than that of aluminum-plated bags.

In terms of performance, pure aluminum bags have better moisture resistance and barrier properties than aluminum-plated bags. Pure aluminum bags are completely protected from light, and aluminum-plated bags also have a certain shading effect.

In terms of use, pure aluminum bags are more suitable for electronic components, cooked food, meat, etc. that require high moisture resistance and vacuuming. Aluminum plating is suitable for clothing, tea, powder, electronic components, etc.

Aluminum foil packaging bags are a very common packaging method in food packaging at present. We commonly use aluminum-plated bags, but in fact, there is also a type of washed aluminum bag. You can tell by the name that they must have subtle differences. Let’s take a look.

What is a washed aluminum bag and what is the difference between it and aluminized bags?

Hear what I have to say:

Washed aluminum bags (also called partial hollow aluminum-plated bags or window bags) are the packaging with the highest printing requirements and the best design effects in China and even in the world. They are very popular in Japan and are widely used in the outer packaging of clothing, food, and toys. ; It is a partially transparent composite bag made of a plastic film composite with partial hollow aluminized film (or called partial aluminized layer de-aluminum). Aluminum washing is to remove or wash off the local aluminized layer on the film.

At present, the aluminum wash bag is a packaging bag product with high printing requirements and a beautiful design effect at home and abroad. It is also a popular and advanced anti-counterfeiting packaging in the world.

The aluminum-washed bag is obviously different from the ordinary composite aluminized bag. The ordinary composite aluminized bag is that the whole bag or the front (or back) of the entire bag is composited with the aluminized film. The aluminum washing bag is different. As long as you want which part of the bag has the luster effect of aluminum and which part has the transparent visual effect, it can be designed and produced, instead of being limited to a certain position or a certain regular pattern. In terms of printing, the washing aluminum bag is better than the ordinary composite aluminized bag. In terms of decoration grade, it is more beautiful and beautiful than the ordinary composite aluminized bag.

There are many different practices and operating experiences for the aluminum washing process, but there are still relatively few companies that can achieve large-scale and high-efficiency production. Now, some users have evolved this process into a transfer printing process. For example, the aluminized film washing process is to apply the aluminum washing process to the cold tear transfer printing process to achieve new effects such as anti-counterfeiting and packaging display.

In general, the aluminum wash bag has the characteristics of clear pictures and texts, high precision, strong three-dimensional sense, similar layers, bright colors, smooth surface, and high wear resistance. From the perspective of commercial security, it is also a packaging form with strong anti-counterfeiting properties, which helps to improve product quality and added value, has stronger product market competition, and is a more high-end packaging method.

Well, today’s knowledge sharing is here, if you are interested, you can follow us, thank you for reading.