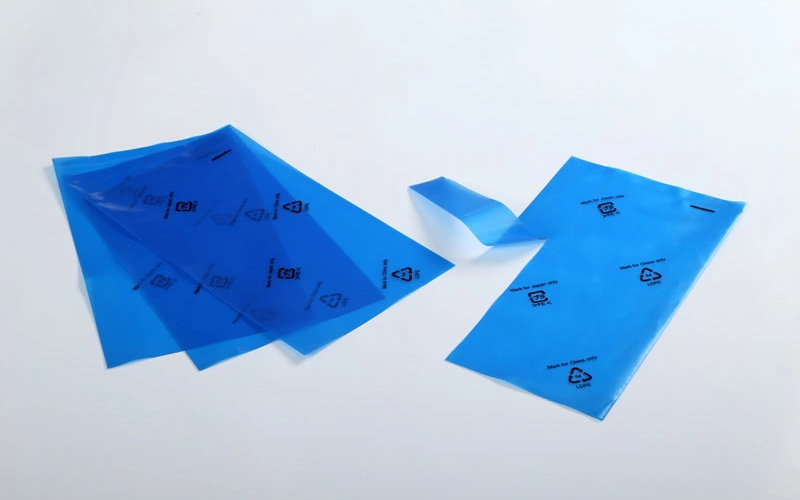

Easy tear film, also known as polyethylene film or polypropylene packaging, is an innovative and versatile packaging material. It has significantly transformed the packaging industry with its ability to be torn open easily by hand without cutting tools. This comprehensive guide provides an in-depth overview of easy tear plastic film, including how it is made through film extrusion process, its key advantages, and widespread applications across various sectors.

Product image:

Performance:

1. Barrier performance: Unique techniques can effectively block air, moisture, light and odor. Film has good oxygen barrier and moisture resistance, which can maximize the freshness and shelf life of packaged products.

2. Anti-fog: In an environment with large temperature changes, easy tear plastic film will not be covered with mist due to gas evaporation, and the contents can still be clearly seen. This makes it very suitable for food and other temperature-sensitive product packaging.

3. High temperature resistance: Some products are packaged at high temperatures, or require high temperature sterilization after packaging. At this time, easy tear film and its carriers need to have high temperature resistance, with a maximum temperature of <135°C. This enables its wide application in medical, electronic and other fields.

4. Sustainability: In an environmentally friendly environment, biodegradable easy tear films are favored by the market, and more degradable packaging is gradually entering the market. This helps reduce plastic pollution and achieve sustainable development.

Specifications:

•Material structure: PP, PET, PE

•Standard size: Custom size

•Production capacity: 50,000 square meters per day

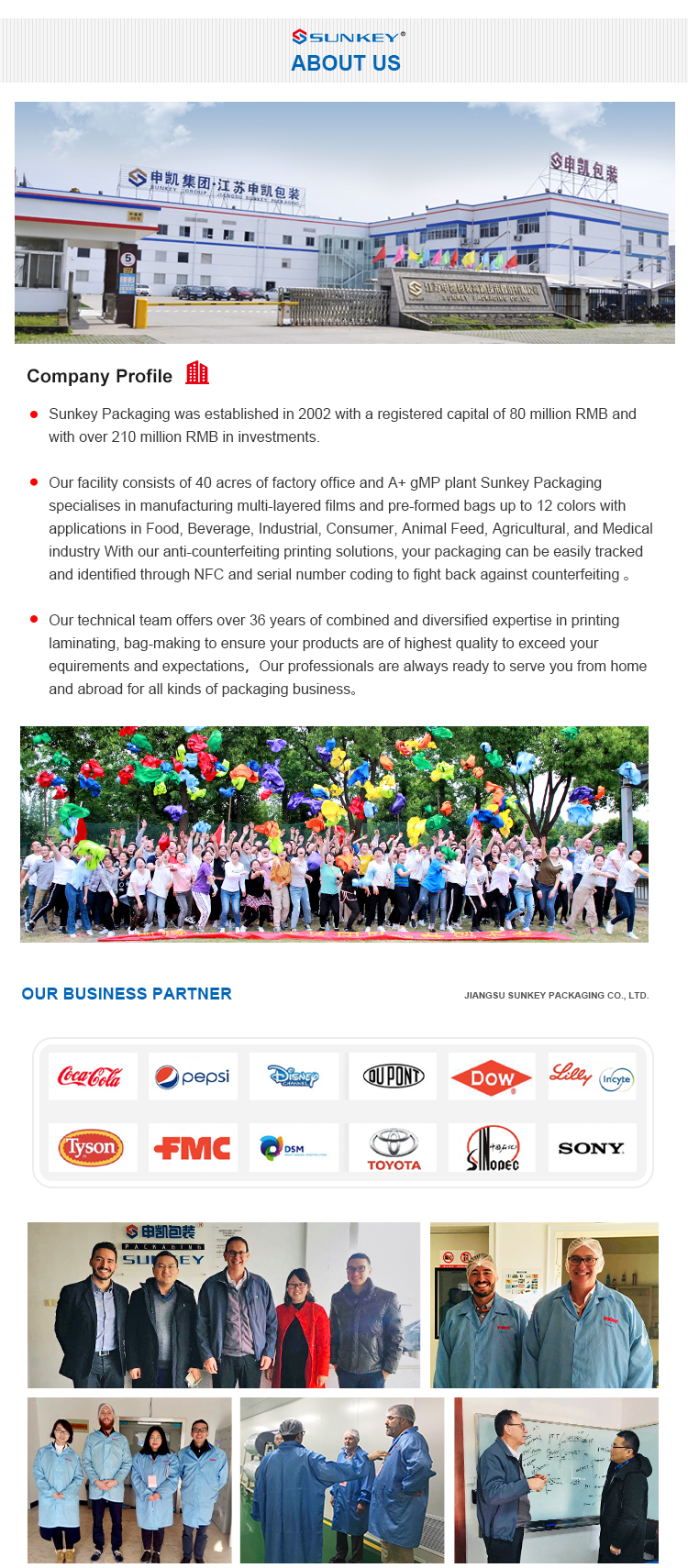

company profile

Company profile: