What is coated silage technology? What is forage film?

At present, the silage technology in the world is coated silage technology. After the harvested corn stalks and fresh grass are crushed, they are compacted and bundled with a strapping machine at high density, and then wrapped with silage plastic stretch film, and the straw bales are in a sealed fermentation environment. Under anaerobic conditions, after 3-6 weeks, the biochemical process of lactic acid-type natural fermentation is finally completed. The crude protein content of the finished product is increased, the pH value is lowered, the total soluble sugar content is increased, and the livestock feed intake rate is reached.

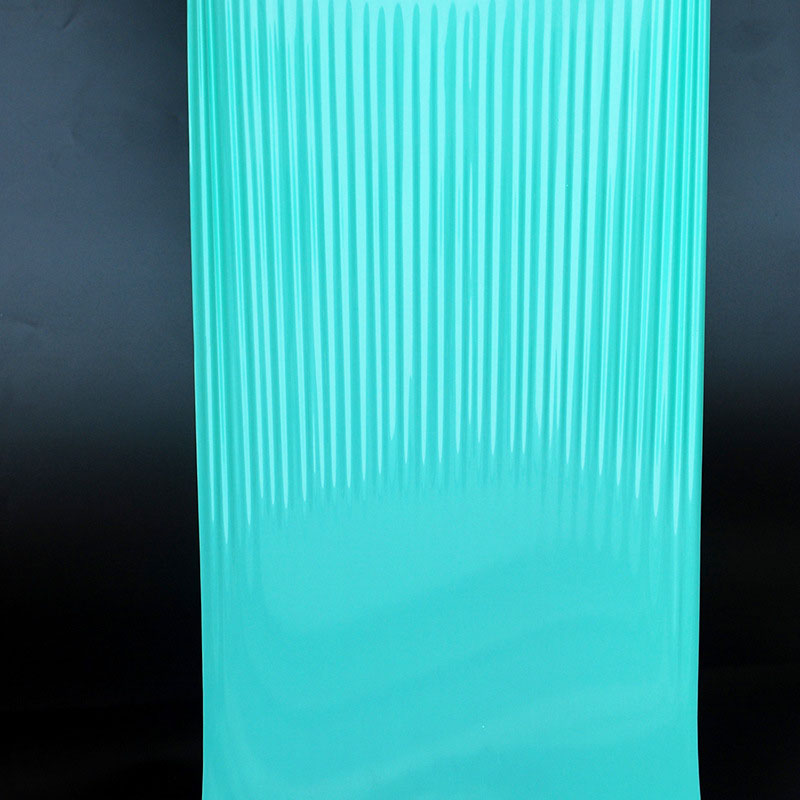

Pasture film is a kind of functional film that helps maintain the nutrients of plants such as grass, corn, grains, and vegetables and prevents them from becoming moldy. The film can be used directly as a packaging film for the above-mentioned plants or be made into a bag before packaging, and can also be used as a covering film for fresh grass, hay, and grains.

Pasture film is currently the world’s advanced silage technology packaging product. It has been used in Europe, the United States, Australia, and other countries and regions and has more than ten years of mature use experience. Our company has introduced a German multi-layer co-extrusion blown film production line to develop and produce The pasture film is made of imported linear low-density polyethylene, metallocene polyethylene, etc. as the main raw materials, and processed by five-layer co-extrusion blown film.

Pasture film is usually available in three colors: white, black, and green. Sunkeypackaging can provide customized services.

What are the applications of pasture film?

- Animal husbandry, grass packaging, silage corn, alfalfa, and other silage cattle and sheep feed

- Packaging of bulk goods

During the research and development of pasture film, Sunkeypackaging and researchers encountered a lot of difficulties. For example, when forage film encounters a low temperature below 0°, how to overcome the cold test and maintain performance is one of the major difficulties. For this reason, researchers continue to improve on the process, constantly adjust the formula to test, and constantly adjust and upgrade the technology, and finally solve this problem.

“When we encounter some problems, we continue to study hard, continue to deepen the research and development cooperation with the school, and make some technical reforms.” In order to test the effectiveness of each formula, Sunkey’s scientific research team has also traveled to the domestic grasslands of Xinjiang, Inner Mongolia, and other large grasslands to conduct experiments, and even went to the United States, Australia, and Canada many times to conduct field trials on local pastures. , “Success is achieved through long-term experimentation.”

After continuous innovation and improvement, the stretch film products now have the characteristics of high tensile strength, good self-adhesiveness, high transparency, anti-ultraviolet, antistatic, silage, antibacterial, natural degradation, light relative density, strong toughness, and energy saving. And, as a packaging material, it is easy to use. At room temperature, only the elastic film needs to be stretched around the packaged part, wrapped tightly, and attached to its end. “The entire stretch-winding process does not require heating, and it can be The consumption is only 1/20 of shrink packaging, which maximizes energy saving; it can be used to bundle single items, or used for collective packaging such as pallet packaging, which can save energy, reduce packaging costs, reduce transportation losses, and improve logistics efficiency. Purpose: There are also many protective functions for packaging and natural degradation functions, which can reduce pollution.”

“Grass film is an improved stretch film”. On the basis of polyethylene PE stretch film, we further develop and improve new pasture film to make the pasture silage longer and maintain a longer fermentation time. Keeping forage fresh for a longer period of time can also play a collective role to ensure that the forage is not polluted, and “quality is equal to that of international counterparts.”

Why do most people choose forage films?

(1) Made of pure polyethylene

(2) Improve the nutritional value of forage during storage

(3) To protect the grass from bad weather, it can be stacked in the open air to prevent freezing and cracking.

(4) Advanced technology and equipment

(5) Very flexible, saving cost and processing time

(6) It is harmless to the environment, the waste stretched film can be recycled and reused, and it is environmentally friendly and pollution-free, and no liquid leaks into the ground.

(7) The light transmittance is low, the anti-ultraviolet ability is no less than 12 months, and the storage period is long.

(8) High-density waterproof core

(9) High tear resistance

(10) It has excellent tensile, tears resistance, puncture resistance, memory, and viscosity migration

(11) Good packaging, can provide rolling protection

Why choose our pasture film?

1. High strength and impact resistance

2. Insulation, rain, and sun protection

3. Efficient and convenient

4. Durable

5. Support customization

6. Wide application

7. Deepen the blue

8. Brand new materials

Instructions for use of pasture film:

During the use of forage film, it cannot be stretched excessively. Suggested stretch ratio: 55-70%.

★ When wrapping the silage, the latter film should cover 50% of the previous film and wrap tightly. After wrapping, the tail end should be inserted into the straw bale film. It is recommended to wrap 3-4 layers comprehensively.

★ After the silage bale is wrapped, if the surface is obviously damaged, it is recommended that it should be sealed with suitable tape immediately.

★ Silage bales cannot be transported on the ground rolling. And stay away from toxic chemical dangerous goods.

★ The storage of silage bales should be far away from plants and livestock, and always check whether they are bitten by rodents such as rats. If damaged, they should be covered with suitable tape immediately.

★ When the pasture film is put on the machine, check whether the upper and lower end surfaces are damaged. Small damage to the end surface can cause the film to be interrupted during use.

★ The unused pasture film should be stored in a cool, dark environment, and prevent moisture and surface mechanical damage.