What is Digital Print for Packaging?

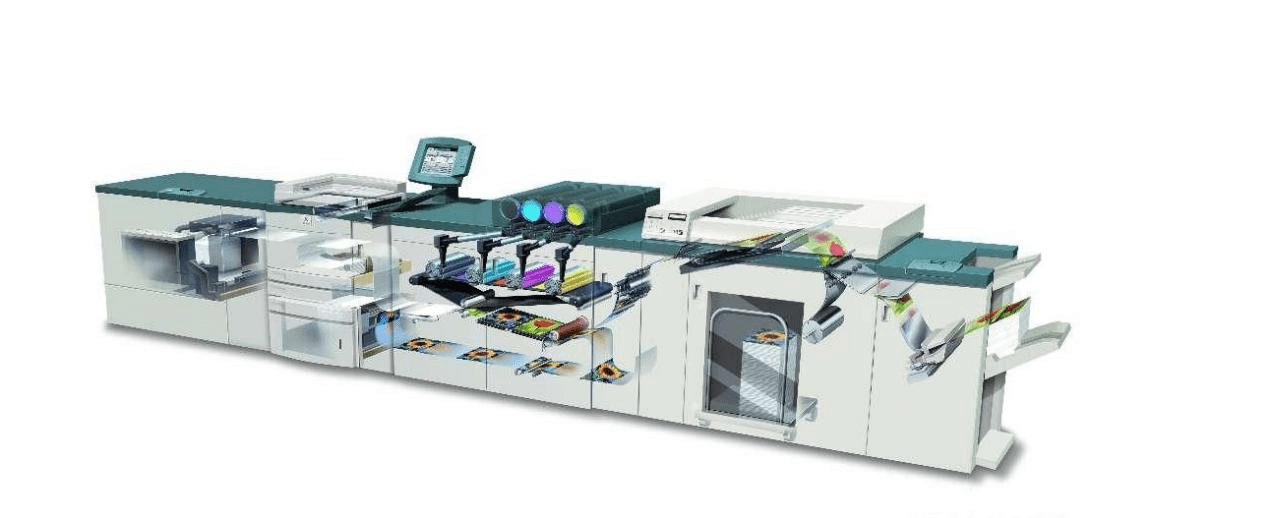

Digital printing is the process of transferring a file on a desktop or any digital storage device to a particular printing substrate through a machine that accepts graphic and text output.

Details on the file are transformed into binary code to keep the data and recreate it efficiently.

Purpose of Digital Printing in Packaging

When compared to offset printing, digital printing requires lower minimum quantities.

Short Runs & Sampling

It is usually cheaper to produce little runs in digital printing than offset printing. When an order of less than a hundred pieces is needed, digital printing is the way to go.

When it comes to custom-made package sampling, digital printing again beats out flexography printing and other traditional kinds of printing.

Thanks to its lower expenses, it is easier to develop package samples with digital printing.

Limitations

The disadvantage of printing digitally is the loss of image quality and, in some cases, only available in smaller paper sizes. It can not print in the PMS Color System, which in turn can not compete with the color precision traditional printers can produce.

Flatbed Digital Print for Packaging

Flatbed digital printing typically utilizes an inkjet printer to replicate digital images.

Inkjet printing is considered to be the future of digital printing. The process utilizes ultraviolet (UV) treatable inks to print digital images on flat surfaces.

This procedure is essential as it can print on numerous surfaces such as wood, metal, glass, and tiles. The innovation can also print on materials that have differing levels of thickness.

Benefits of Flatbed Digital Printing

- Consistently have higher quality: True digital flatbed technology does have a higher preliminary cost than its competitors, but it does print in greater detail and has a higher level of accuracy & repeatability.

- Eco-friendly: Flatbed printing is also more environment-friendly than conventional printing as it produces a lower amount of waste cartridges and produces lower air contamination. It leaves behind a smaller sized carbon footprint.

- Flexible and low cost: Flatbed printing is outstanding for customized and industrial packaging. Its lower cost increases the ease of customization and enables clients to develop their styles at a low price.

- Quick and effective production time: It conserves a lot of time compared to traditional printing as there is no need to constantly alter plates, as the technology does not utilize any plates.

- Private customization: Based on these advantages. We can help customers develop private customized products to meet the needs of all users. For example, private customized pattern printing, private customized text printing, etc.

Digital printing does not require the use of plates as offset or conventional printing needs. The procedure mainly uses toner and liquid ink.

In lots of circumstances of digital printing, unlike standard ink, the ink used will not permeate the substrate being printed on. The ink produces a thin layer on the substrate, and the ink further adheres to the surface through UV treating or laser heating.