What is GRS?

The abbreviation of GlobalRecycledStandard certification is GRS, which was originally drafted by ControlUnion in 2008. On January 1, 2011, the ownership of this standard was handed over to Textile Exchange. GRS is international, spontaneous, and complete. Through third-party certification, it is a practical industrial tool to examine the company’s product recovery rate, product status, social responsibility, environmental protection, and chemical restrictions.

What is the Purpose of GRS?

In order to prevent waste from being landfilled and recycled, and at the same time reduce the over-exploitation of energy, all human beings are advocating the use of recycled materials, especially the younger generation who are more environmentally conscious and prefer environmentally friendly products for shopping and consumption. Whether it is an environmentally friendly product, consumers can check through the “hang tag”, and some brands can be traced by scanning the code. Increased awareness has given a big boost to the production of recyclable materials.

Drive innovation in solutions to quality issues in the use of recycled materials. Ensuring more sustainable recycling and disposal of materials in final products and reducing the harmful impact of production on people and the environment are all goals and objectives of GRS. The certified company must clearly state the proportion of pre-consumer and post-consumer waste used throughout the declared GRS product. The responsible person of the registered company Documented procedures for minimizing and monitoring waste and emissions; etc.

What are the Benefits of GRS Recyclable Certification?

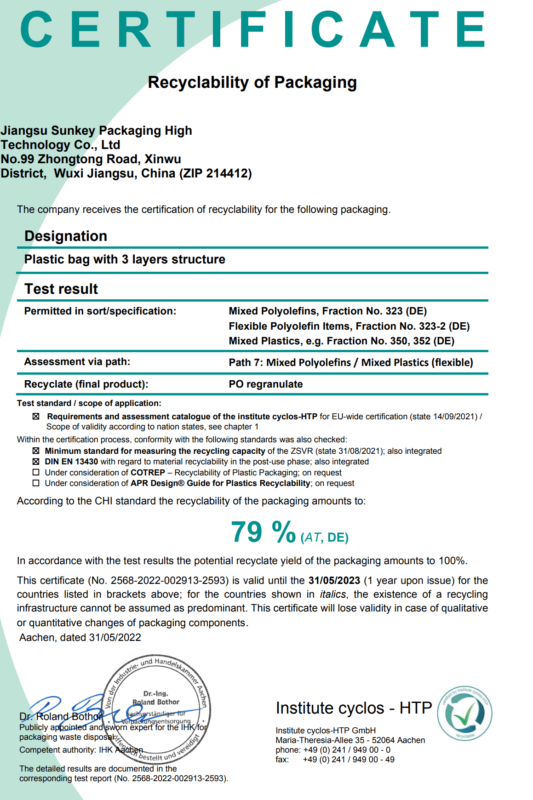

Environmentally friendly packaging bags are being applied to more and more industries at present, which is a trend and a necessity to protect the environment. Companies such as plastic product packaging, handbags, etc., such product export, may face the problem of customers requesting GRS certification.

In the production process, the factory that processes and produces also needs to be certified by GRS, then the product made is considered a GRS product, and a transaction certificate TC can be issued. If the purchased raw materials have passed the GRS regeneration certification, the processing factory does not have GRS certification, and the produced products cannot issue a TC transaction certificate. The GRS regeneration transaction certificate TC cannot be issued.

The price of GRS food-grade safety bags is also much higher than that of ordinary packaging bags. Today, GRS has been detonated by brands such as ZARA, H&M, ADIDAS, UNIQLO, NIKE, IKEA, GAP, and other brands throughout the entire industry chain, linking all supply chains. Traditional commercial recycled materials, because of their unstable quality and poor physical properties, are mostly lower in price than new materials, and their performance is also worse than new materials.

To meet the requirements of brand customers and meet internationally recognized environmental protection standards (such as GRS), the cost of GRS-certified recyclable packaging is generally about 10% higher than that of new materials, the quality is more stable, and the performance is better than traditional recycled plastic bags. This is a good phenomenon.

Summary

Under the guidance of this trend, the world will become more and more beautiful, people’s lives will become better and better, and a harmonious scene.

Sunkeypackaging is always committed to protecting the environment. We prefer to produce environmentally friendly products, and drive innovation in solutions to quality issues in the use of recycled materials. Warmly welcome your contact with us.