Flexible food packaging gives brand owners the opportunity to attract customers and interact with food benefits, allergen cautions, and traceability details. The ability to offer details on the packaging without jeopardizing the food’s quality or security is important.

Constant inkjet (CIJ) printing is a flexible coding technique to produce clear, readable alphanumeric codes on irregular and curved surfaces such as pouches, bags, and packs. Food manufacturers usually utilize CIJ printers on their packaging lines to printmaking information, expiration dates, and other variable data directly onto flexible food packaging.

Satisfying Regulation Requirements

Ink plays a crucial role in food safety as it may enter into contact with food due to ink migration or the nature of the packaging. Generally, if it is fairly expected that the ink might reach the food, its formula should follow Food and Drug Administration policies in the U.S., Health Canada and Canadian Food Inspection Agency standards in Canada, and other worldwide guidelines depending on the food’s destination.

While particular inks are not recognized by the FDA as appropriate for direct and indirect food contact, the Code of Federal Regulations (CFR) Title 21 regulates food contact materials. The CFR includes basic provisions suitable to indirect food additives and a threshold of guideline for compounds used in food contact. Much more strict, Switzerland’s ordinance 817.023.21 lists particular ink parts permitted food contact printing and determines migration limitations of inks printed on particular substrates. As one of the most restricting regulations, it is frequently referenced worldwide by manufacturers to identify an ink’s security for use in food applications.

While CIJ printing utilizes much less ink compared to full coverage printing, the possibility of substances moving through packaging is still possible depending on the ink type and quantity utilized in addition to the type of packaging. Migration tests should be performed to determine exactly what compounds can travel through the packaging and make contact with the food. Even if the ink is not anticipated to have contact with food, the food manufacturer must guarantee that the material forms a functional barrier between the food and ink.

Direct Food Contact and Food Grade Inks

Food-grade printing ink might be needed for certain flexible packaging applications, like when a batch number is printed on a flavor pouch that is placed into a box of pasta. The printed batch number will deliberately make contact with food. For that reason, the ink’s parts ought to satisfy the requirements of food-grade ink.

When direct food contact is meant, food-grade inks manufactured under Excellent Manufacturing Practices and approved for the application needs to be used. These food-grade inks usually include solvents such as beverage-grade ethanol, food-grade acetone, and potable water. Once printed, the majority of the solvent evaporates in the air, leaving only recurring trace quantities of solvent on the surface. For FDA compliance, a CIJ food-grade ink’s components must be recognized as enabled food additives on the CFR 21 list and used for their desired purpose.

Indirect Food Contact

The FDA defines indirect food contact as when an additive, such as a printing ink, accidentally comes into contact with food as part of the packaging. The food manufacturer is accountable for checking the application to guarantee that the packaging is serving as a practical barrier in between the ink and food and that the completed bundle meets all relevant regulations. The ink maker is accountable for supplying users with a complete list of each ink’s elements to aid in testing.

Printing on Flexible Packaging

While numerous CIJ ink compositions might be similar to flexographic, lithographic and other printing inks, the key distinction remains in the printing method and the special demands of a CIJ printer. CIJ inks have considerably lower viscosities than other inks and are printed with a non-contact technique, making good adhesion challenging. CIJ inks must also be able to hold an electrical charge to allow the variable positioning of each drop. While total substrate protection would be difficult, a CIJ ink’s chief task is to produce clear, understandable alphanumeric codes on the food’s packaging.

Another code-printing technology, thermal transfer overprinting (TTO), has its advantages with flexible packaging consisting of the capability to produce high-resolution codes and large quantities of text. Yet CIJ stays an outstanding option for many manufacturers who are searching for combination options. CIJ printers can apply codes before or after the film is formed and the product is packaged. In addition to inks of various colors with food-grade, fast-drying, and high-contrast properties, specific CIJ inks are specifically crafted for printing on versatile packaging consisting of BOPP, LDPE, and PE.

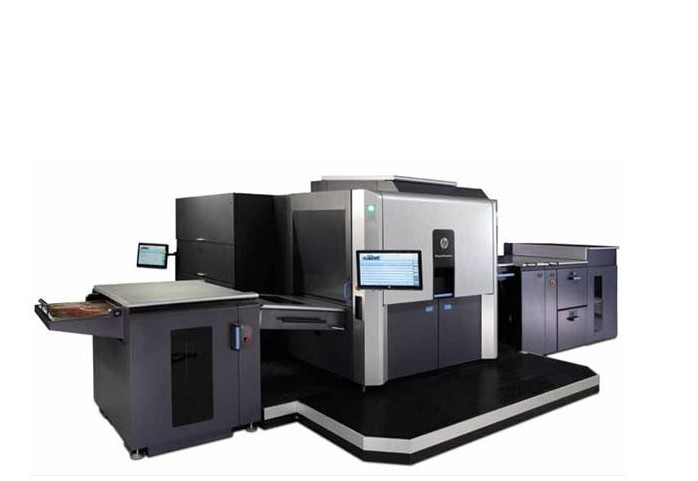

How does Sunkey Packaging ensure the food safety of digital printing inks?

- Through the use of food-safe inks, the inks used in HP digital printers are all FDA-certified inks that can be directly contacted with food. The main solvent used is ethanol, which is non-toxic and harmless.

- Through the use of food-safe inks, the inks used in HP digital printers are all FDA-certified inks that can be directly contacted with food. The main solvent used is ethanol, which is non-toxic and harmless.

As a professional flexible packaging company, Sunkey Packaging has been committed to the research and development of innovative flexible packaging technologies and has also invested a lot in environmental protection and food safety. Sunkey Packaging specializes in providing customers with flexible packaging solutions.