Degradable packaging is a new type of packaging developed in recent years, including plastic substitute packaging made of degradable polypropylene film, food packaging based on wood pulp, nanocellulose fibrils, and hydrophobized modified nitrocellulose. Food packaging prepared using sweet potato starch, hydroxypropyl methylcellulose, plant fiber modifiers, etc., and aliphatic polyesters with both biocompatibility and degradability prepared by ring-opening polymerization of cyclic lactones material, which is favored by the market for its environmentally friendly properties.

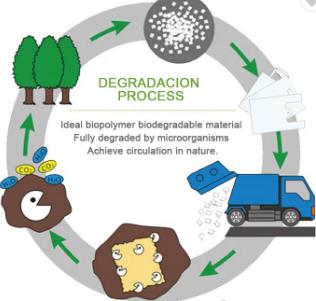

Degradable food packaging is made of naturally degradable materials such as starch and its derivatives, proteins, cellulose, chitosan, and polylactic acid as raw materials, and can be degraded by chemical modification processes and blending equipment. Degradable materials for food packaging can be divided into three categories according to the degradation mechanism: photodegradation, biodegradation, and composite degradation. They have broad application prospects in food inner packaging film, coating film, food packaging film, food packaging, catering, etc. It is used for the storage and preservation of meat products, dairy products, baked products, and fresh fruits and vegetables.

The polyhydroxy acid biodegradable nanocomposite film material produced by the blown film/cast film process can replace the aluminum foil rolling composite packaging, which can reduce the amount of solid waste by 20% to 30% every year; it is prepared from wheat bran and soybean raw materials. The grain matrix film has good moisture-proof and moisture-proof and inhibits the oxidation of food components; the film made of animal protein collagen is used to package meat food, and the film is made of methyl hydroxy propionyl cellulose is used for forming and filling. , sealing and vacuum packaging, etc., can meet the needs of long shelf life of food, and no packaging waste will be generated after use.

Polylactic acid (PLA) is currently the most widely studied and applied biodegradable material, which is polymerized from lactic acid. There are generally two polymerization methods: one is to use corn, straw, and other renewable resources as raw materials, and the lactic acid monomer is directly polymerized in the solution state; the other is to obtain cyclic dimer lactide from lactic acid and then polycondensate to form a polymer. Lactic acid, also known as the two-step process, is a more mature process. In addition to good biodegradability and biocompatibility, polylactic acid also has good physical and mechanical properties, such as strength, gloss, transparency, and heat resistance. After degradation, carbon dioxide and water are finally generated, which are recognized as environmentally friendly materials, and even the human body also contains lactic acid in a monomeric state.

In some important fields, especially in the express green packaging industry, the product price of degradable materials is high due to the unit price of raw materials, and the degree of application is still low; in food packaging and other industries, there are still limitations on product performance and use, and it is necessary to continue to study how to reduce and traditional material performance gap. At the same time, efforts should be made to develop and promote green products, explore new business forms and models for recycling and recycling, reduce packaging pollution; strengthen the sorting, recycling, and transportation of packaging waste, and standardize the recycling and harmless disposal of waste. There is a long way to go to get rid of the “plastic” bondage.