As a Fortune 500 food company, Tyson Foods usually invests a lot in the research and development of new products. Sometimes the time to market for new products is very urgent, and the sales volume is also unknown. The demand for packaging materials is not only fast, usually 5 days Finished products, and the quantity is very small. Using traditional printing composite technology to produce not only has a high MOQ but also cannot keep up with the time. It takes at least 3-5 days to make the cylinder.

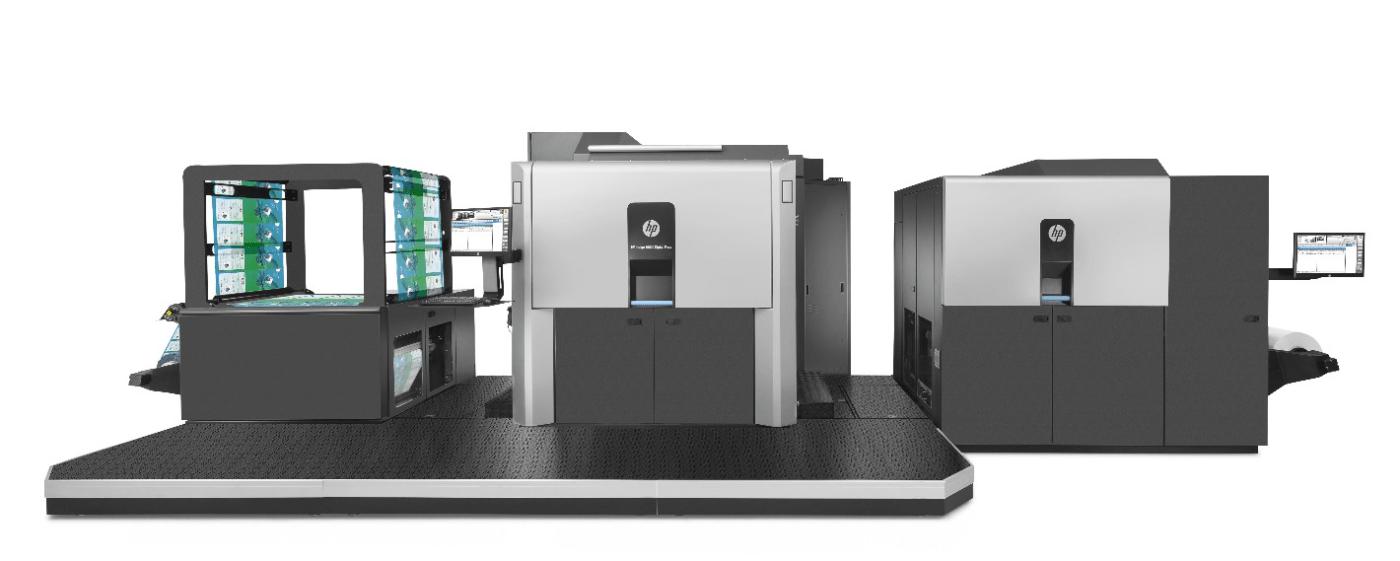

In order to meet the needs of Tyson Foods, Sunkey Packaging uses advanced technology to specially design a set of rapid sample production process for Tyson Foods. First of all, we cooperate with design companies to assist customers in designing product pictures and digital artwork. Then upload the digital artwork to the HP printer through digital printing, and use the materials required by the customer to print the required patterns. Then production is made into a finished product through a rapid laminated ——curing—— bag manufacturing process. The shortest time to produce a complete product is 3 days, and the longest time is 7 days.

This set of digital printing process is not only used for Tyson, but also for any other customers with similar flexible packaging needs. It can not only shorten the time for customers to market new products but also save customers a large part of the cost, including the plate fee, Bag waste costs caused by traditional craftsmanship which has a large MOQ but insufficient new product sales. It can also launch multiple types of different categories, different design styles, different product tastes, etc., to test the market’s response and finally select the best-selling product in the market.

Digital printing, as the most advanced printing method in the world, will be widely used in all walks of life in the later period. As a leading enterprise in the flexible packaging industry, Sunkey Packaging always takes R&D and innovation as the premise and aims to create more value for customers. Provide customers with more professional, innovative, and perfect flexible packaging solutions.