Here, we will cover the difference between two primary printing techniques, named digital and offset printing. If you want to make your custom packaging game strong, then know the difference between significant types. Packaging plays a vital role in attracting potential customers. Thus, if we see this from a business perspective, the packaging industry will witness constant changes. If you are concerned with the packaging, then read this post.

An intro about digital and offset printing:

What type of printing is better? Should I prefer offset or digital printing? These are common queries that pop up in the mind of every person who runs a custom packaging business. So, here is the detailed answer to this question.

What is offset printing?

Offset technology uses plates that are made up of aluminum. In commercial language, we may call it “Litho-offset.” However, these plates use to transfer the image on a rubber cylinder. Later the rubber cylinder rolls that image on a paper sheet. Apart from the paper, the rubber blanket can print on wood, cloth, metal, or leather. So, we call it as offset printing because, in this, we don’t print the image directly on the paper. An American discovered this process in 1904 and soon built a press to take advantage of the features. However, if you run a business that constantly needs custom packaging, then offset printing should be your ultimate choice.

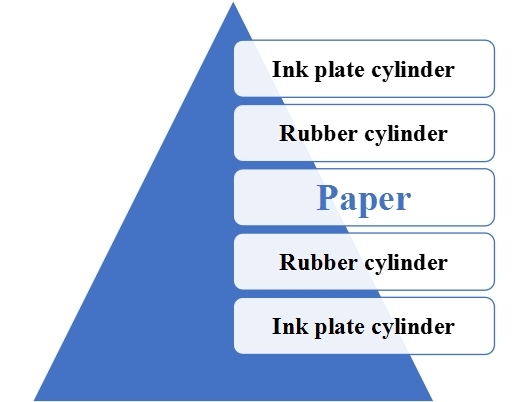

It is the best technology that provides the best colors, crisp, and professional-looking printing without shadows. Here is the chart that is elaborating the detailed process of this type of printing.

Offset printing requires a separate cylinder for each color or ink that you are going to use. Moreover, you can use different types of plates and inks according to the requirement and length.

Pros and cons of offset printing:

| Pros | Cons |

| Superior image quality | It doesn’t go best with low volume jobs |

| Best color consistency | It takes more time for plate production |

| It works best on all types of material | In case of error, you have to start the whole process all over again |

| You get what you pay for | |

| Best for larger jobs |

What is digital printing?

Digital printing is different from offset because it doesn’t require plates for printing. Thus, this type of printing works based on toner or liquid ink. There are many pros to using digital printing. It helps when you need to print variable data in which every piece requires unique code. So, digital printing can easily handle this type of need. It means that both types of printing have different fan bases when it comes to custom packaging. Many flexible packaging manufacturers are addressing the packing needs of this industry.

Pros and cons of digital printing:

| Pros | Cons |

| Works fast and well on time | It has few options for printing material |

| Each print is identical | There are fewer color choices |

| Fewer chances of errors | Costs high for large volume printing jobs |

| Works best for low volume jobs | Deliver slightly less quality and sharpness in printing |

| You can quickly change the information for different printing batches |

Difference between digital and offset printing:

If we talk from the business perspective, both types are a perfect fit with some minor differences. For instance, offset printing is suitable for companies that need identical printing copies in bulk. On the other hand, digital printing is best for business that needs same custom packaging in less quantity. But both types produce custom packaging prints that are incredibly high in quality. Apart from this main difference, here are the following other points that are will elaborate on the terms.

Technological difference:

Many top-class flexible packaging manufacturers find both types equally beneficial. But if we talk about the technological difference, then it’s about how the image transfer on paper. As a result, it directly affects the per-unit price of the printing. Generally, offset printing is more time-consuming and expensive than digital printing. We already discussed that offset technology involves more cylinders that increases the overall cost. On the other end, digital printing needs minimal setup, and it is easily transferable.

Sheet sizes:

If we discuss digital printing, it typically requires a more miniature sheet that is 19 inches. In some conditions, the sheet size could be around 29 inches. On the other side, in offset printing, the sheet size is about 29-40 inches. So, this sheet size is perfect for those types of printing that aren’t possible on a small sheet. For instance, take the example of posters, books, large covers, and brochures. Apart from this, always keep in mind there are specific dimensional printings that aren’t possible on a digital printer. However, for comprehensive formats, we can take examples of custom packaging materials, plastic, etc.

Color representation:

Every printing technology generates different colors from one another. So, you have to wisely choose the printing type that can create the colors that you want. But to some extent, offset printing makes the best colors than digital printing. The color contrast of the offset printers is superior to the digital ones. Offset printers use Pantone ink that is more precise. Thus, the top-notch brands prefer offset printing because, for them, color consistency matters the most. In simple words, large brands use offset printers because the color contrasts are worth them like money.

Price difference:

The other main difference between offset and digital printing is about price. Digital printing is cheaper due to a significantly smaller setup. However, if you own printing business, then you can easily prepare prints at an affordable price and more efficiently. But if you have an offset printer, then it will take a considerable amount of time. The offset printers require multiple plates that are properly inked to create the print.

How to decide between offset and digital printers?

After reading the whole conversation, if you aren’t still sure between digital and offset printing, here is the crux. Many flexible packaging manufacturers ask the following questions before deciding on the printer.

- Companies ask themselves about projects’ size.

- They decide printer type based on the time frame

- Printing material plays an important role to make the decision

- Do they need something special? If a business wants to print something unique, then digital printers are best.

- Businesses’ decisions based on color flexibility

Apart from this, the decision is based on the type and quantity of the products you want to print. For instance, if you need more than 500 copies, then offset printing would work. But if you need less volume of custom packaging, then digital printing would work.

Final verdict:

Nowadays, most businesses are making decisions and choosing the best technology for custom packaging. So, the volume of the printing material plays a key role while making the decision. So, if you are in search of the best quality printers for your business, then do your quest before making a final decision. Many flexible packaging manufacturers do printing and packaging both for their customers. But don’t forget to check online reviews and ratings before placing an order.