Among all kinds of products, customers always choose only the products they like. In addition to the popularity of the product itself and the satisfaction with the product itself, coffee bags are used as coffee packaging bags. The concept of coffee bag packaging design is affecting influence consumers’ purchasing decisions.

Four common types of coffee packaging on the market:

1. Flexible non-airtight packaging: This is the most economical packaging. Some local small businesses usually use this kind of packaging, because they can ensure rapid supply, and the coffee beans can be used up in time. But coffee beans that use this packaging method can only be kept for a short period of time.

2. Air-tight packaging: After the bag is filled with coffee, vacuum and seal it. Due to the formation of carbon dioxide during the roasting process, this package can only be packaged after the coffee has been left for a period of time to degas, so there is a storage interval of several days. Coffee beans last longer than ground coffee. Low cost as no separation from the air is required during storage. Coffee in this packaging should be used up within 10 weeks.

Why install a one-way exhaust valve? In the early roasting stage of green coffee beans, the living water in the cells begins to evaporate, carbon dioxide is continuously generated in the process of continuous absorption of heat, and the cell walls gradually harden and begin to expand. As the roasting process continues downward, the pressure inside the coffee bean continues to increase, and the coffee oils are drawn into the tiny pores in the cell walls, creating a seal that traps carbon dioxide and other aromatic substances in the cell walls. This is the origin of the “coffee aroma”. But as long as it is roasted coffee beans, carbon dioxide will be continuously produced in the later stage, that is, to complete its degassing process. Another point is: “oxygen”, the most direct reaction that oxygen brings to coffee beans is “oxidation”. That is one of the “culprits” that makes coffee lose its flavor. This reaction begins as soon as the coffee beans leave the roaster. If the beans are ground into powder, the surface area of the coffee exposed to the air will be greatly increased, which will greatly speed up the oxidation process. Both oxygen and carbon dioxide can seriously affect the freshness and taste of coffee beans, causing the optimal taste of the brew to be greatly reduced. The one-way exhaust valve is a small accessory on food packaging. Its function is to take carbon dioxide out of the bag in time, while oxygen and pollutants cannot enter the bag so the packaging of coffee beans is in a state of only entering and not entering. , in this way to protect the freshness of the contents of the bag.

3. One-way exhaust valve packaging: After roasting, the coffee is placed in a special packaging bag with a one-way exhaust valve. This exhaust valve allows gas to go out but not in.

4. Pressurized packaging: This is the most expensive method, but coffee can be kept for up to two years in this packaging. After a few minutes of roasting, the coffee can be vacuum-packed, with some inert gas added to keep the right pressure inside. The coffee beans are kept under pressure, allowing the aroma to flow onto the fat, thereby improving the aroma of the beverage.

Common coffee bag types:

1. Stand-up pouch: The stand-up pouch is a relatively novel form of packaging, which has advantages in improving product quality, strengthening the visual effect of shelves, being portable, easy to use, fresh-keeping and sealability. The stand-up pouch is laminated by PET/Foil/PET/PE structure, and can also have 2 layers, 3 layers, and other materials of other specifications, depending on the different products to be packaged, and an oxygen barrier protective layer can be added as needed to reduce the oxygen permeability. , extending the shelf life of the product.

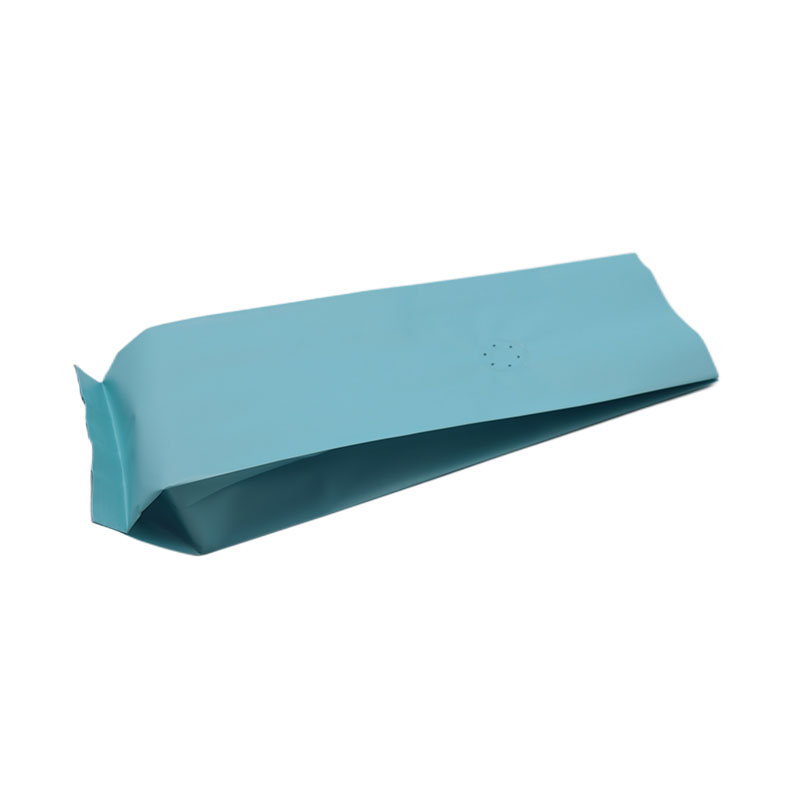

2. Organ bag: Fold the two sides of the flat pocket into the inside of the bag body, and fold the original oval-shaped bag into a rectangular opening. After folding, the sides of the bag are like tuyere leaves, but they are closed. Name this bag the organ bag. The advantage of the organ bag is that it reduces the floor space, the packaging is beautiful, and it retains the original advantages of the flat bag, that is, it can be printed, and the printing content is much richer than that of the flat bag.

3. Eight-side sealed bag: As the name implies, the octagonal seal has eight sides. The eight-side sealing bag is beautiful and elegant, and the shelf display effect is perfect, and other processes such as zipper can be attached; the flat-bottomed eight-side sealing has a large capacity; it can be made according to the combination of different materials, thickness, moisture, and oxygen barrier, metal effect, and printing effect. Bags with different performance characteristics to meet various food performance requirements and prolong food shelf life.