China’s flexible packaging industry emerged in the 1970s, the annual growth rate reached more than 15%, packaging printing industry occupies a large proportion. Flexible packaging in product research, product development, market testing, production and manufacturing, product launch, sales and the whole product life cycle, the use of digital process can be very good cost savings. Although the cost savings are limited, the value added space is unlimited. In addition, there are many value enhancements to the digital process, such as the optimization of printing costs and overall costs, and the promotion of brand growth through better customer experience.

The 5G era has changed the flexible packaging factory mainly in five aspects: digital R&D and design, the whole process of production, warehousing and logistics, order acquisition and after-sales.

1.Digital R&D design

Digital R & D design saves development cost, improves product development efficiency and shortens the time needed for development verification. The intellectualization of the whole production process can improve the quality of flexible packaging products and play a role in the rational allocation of production factors throughout the processing of production data.

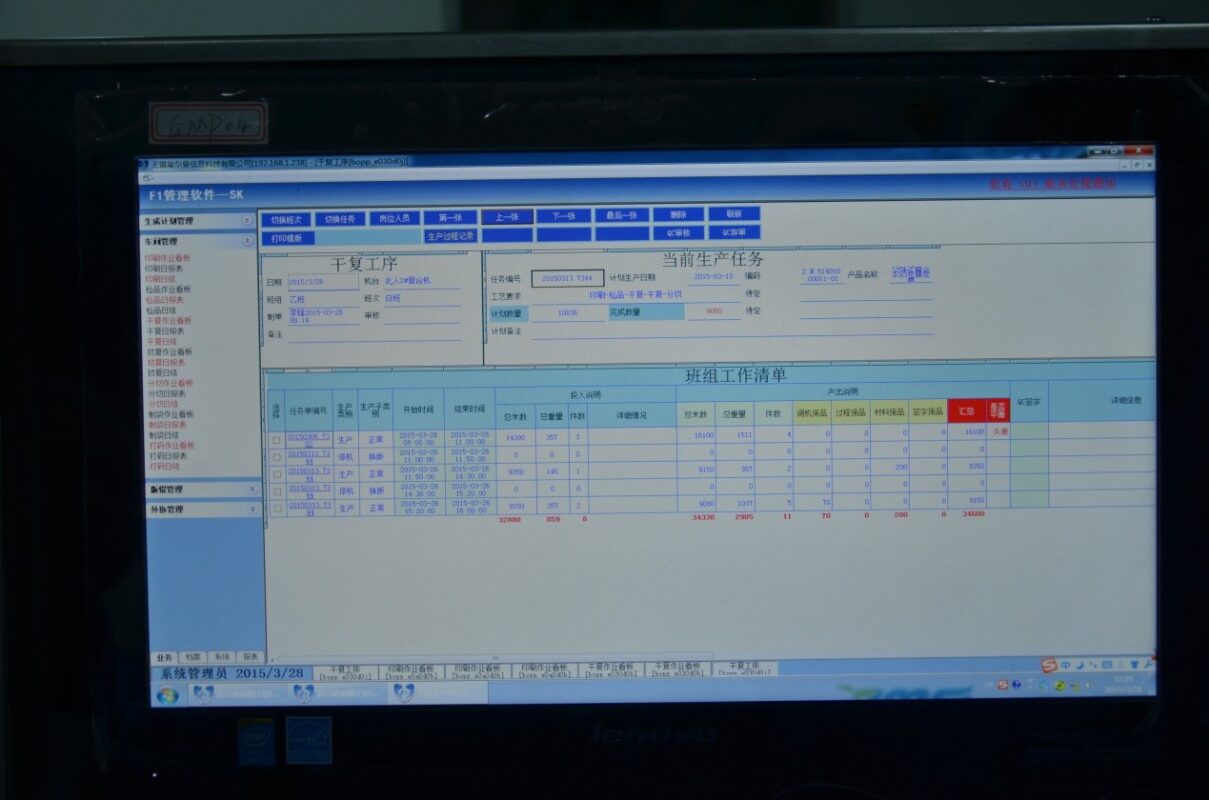

2.Whole-process intellectualization of production

In order to realize the intellectualization of the whole process of production, the flexible packaging factory will adopt the way of establishing the information platform and make the whole process of production under the monitoring of the information platform by using a large number of different types of sensing sense. In this way, the intellectualization of the whole process of production can be realized in the real sense.

If an flexible packaging factory wants to realize intelligent manufacturing, it must apply big data analysis. Intelligent manufacturing systems undertake the tasks of analysis, reasoning, judgment, conception and decision making, which need to be built on the basis of big data analysis.

3.Intelligent warehousing and Logistics

Logistics warehouse in the entire product manufacturing, sales process accounts for a considerable part of the proportion, affecting the profits of enterprises. Therefore, the establishment of intelligent logistics warehouse system can effectively improve operational efficiency and save costs, and then achieve profit increase.

Logistics warehouse is mainly in the express logistics enterprise, which has been widely applied in many express companies have now established intelligent, automated express sorting system, such as jingdong enterprise, so that we can clearly express the sorting of time saving, improve the sorting efficiency of delivery, speed up the sorting of express delivery, saving manpower, to achieve profitability.

4.Order to obtain

The intellectualization of order acquisition is to analyze and acquire by means of big data. Users browse the content of websites or client platforms in daily life to analyze their preferences for soft packaged goods or services, so as to realize the personalization of soft packaged goods and realize the intellectualization of order acquisition.

5. after-sale

In after-sales service, is the product of remote operations services, after-sales service in traditional manufacturing industries are mainly in the form of artificial, and this form tend to appear after ability is insufficient and after-sales cost big phenomenon, the emergence of this situation not only affects the user’s service experience, also will make the enterprise profit decline. Therefore, flexible packaging factories like Sunkey use one bag and one yard function on some products like custom packaging bags and custom packaging films,Which can make enterprises more convenient to track the later use of products, and find some basic information of problem products quickly and easily. This not only helps customers solve after-sales problems, but also saves manpower. Eventually achieved a double win effect.