Easy tear plastic film,also known as polyethylene or polypropylene packaging film, is an innovative and versatile packaging solution. It has significantly transformed the packaging industry with its ability to be torn open easily by hand without cutting tools. This comprehensive guide provides an in-depth overview of easy tear plastic film, including how it is made through film extrusion process, its key advantages, and widespread applications across various sectors.

What is Easy Tear Plastic Film?

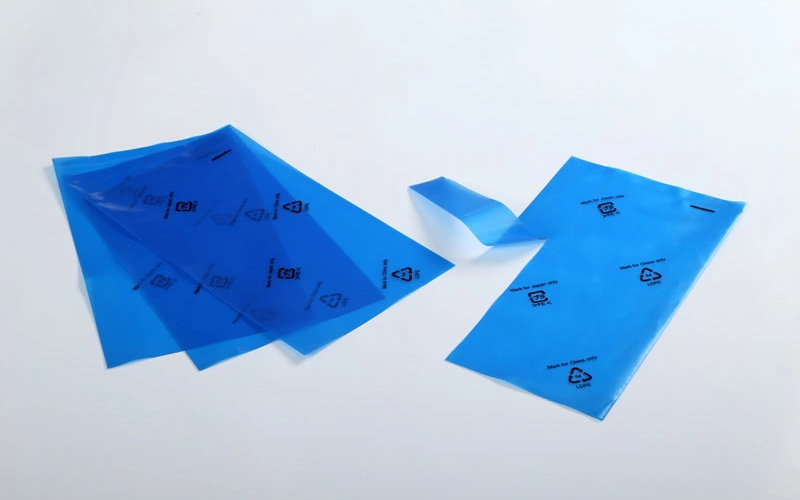

Easy tear plastic film is a type of polyethylene (PE) or polypropylene (PP) film specifically engineered to be opened easily without scissors or knives. Made from durable yet lightweight materials, easy tear plastic film offers a smooth surface that can be torn in a controlled manner by applying pressure with hands. Despite its tearability, it provides exceptional barrier protection against external elements like moisture, oxygen, and light. This helps extend the shelf life of packaged products.

How is Easy Tear Plastic Film Made?

Easy tear plastic film is manufactured through a film extrusion process, where polyethylene or polypropylene pellets are melted and extruded into a film. The film is then mechanically altered through a stretching and orientation process to align the molecules in a specific direction. This molecular alignment results in an easy tear effect in one direction, while the film remains intact in the other directions. Advanced technologies can also be used to control the thickness and strengthen certain areas of the film to create different tear patterns.

The Key Benefits of Easy Tear Plastic Film

Convenience and Ease of Use

The biggest benefit of this film is convenience for customers, who can open packages easily without any tools. This significantly enhances the user experience, especially for frequently accessed products. The easy tear effect also allows controlled tearing and prevents uncontrolled ripping.

Cost Effectiveness

Compared to other packaging options, easy tear plastic film is more affordable and cost-efficient. It also reduces labor costs associated with using cutting equipment. This makes it an ideal choice for large volume or high-speed packaging applications.

Improved Product Protection

Despite its tearability, easy tear plastic film provides exceptional barrier protection against moisture, oxygen, and light. This helps preserve the quality and extend the shelf life of packaged products, especially food, medical, and electronics items.

Customizability

Easy tear plastic film can be customized according to different tear patterns, strengths, thicknesses, and aesthetic qualities. This allows brand owners and manufacturers to design unique, brand-aligned packaging that enhances customer experience. Custom printing, embossing, and artwork can also be applied to the film.

Common Applications

Easy tear plastic film is used for packaging across many industries, including:

•Food: Snack bags, cheese wraps, bakery bags, etc. Easy tear film keeps food fresh while allowing easy opening.

•Medical and Pharmaceutical: Bandages, gauze pads, surgical gloves, etc. Easy tear film facilitates quick access to medical supplies while maintaining sterility.

•Electronics: Phone pouches, cable wraps, component bags, etc. Easy tear film protects sensitive electronics from physical and environmental damage.

•Household goods: Bin bags, cling wrap, pet food bags, etc. Easy tear film seals in freshness and contains mess during storage and waste disposal.

•Agriculture: Seed bags, fertilizer bags, pesticide bags, etc. Easy tear film safely contains and protects agricultural goods from external conditions during storage and transport.

In summary, easy tear plastic film is a versatile and advanced packaging solution with significant benefits for customers, brands and manufacturers. With its ability to be opened easily without tools, easy tear plastic film offers convenience and enhances user experience. It is customizable, cost-efficient and provides maximum product protection. The application of easy tear plastic film across industries contributes to a high-speed, automated and sustainable future of packaging.

If you want to know more detail, contact us.